Movie

DCN Series

For when batch washer processing capacity isn’t enough!

Containers are carried on a conveyor belt for high-volume processing!

Is This Possible?

Optional Products to Meet Needs

- When you have no steam boiler…

-

Electric heater

Water can be heated using an electric heater and used for washing.

* Make sure water temperature is above 70℃.

- When having one person to do the washing…

-

Return Conveyor

Attaching a return conveyor at the exit of the washer makes it easy for one worker to load and unload.

- When you want to reduce running costs… this reduces the amount of fuel used!

-

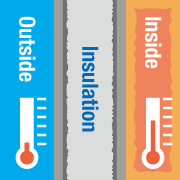

Isolation Chamber

Doubled metal sheet, and filled insulation material between them. Thermal efficiency is improved by reducing heat radiation from metal sheet.

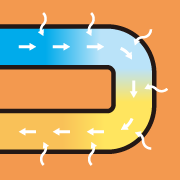

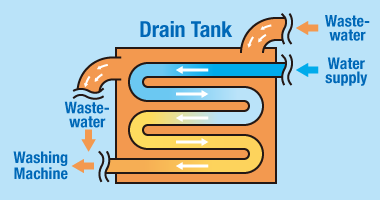

Wastewater and exhaust heat recovery device

Warming up using water by heat recovery from wastewater.

- When you want to reduce running costs… this reduces the amount of water used!

-

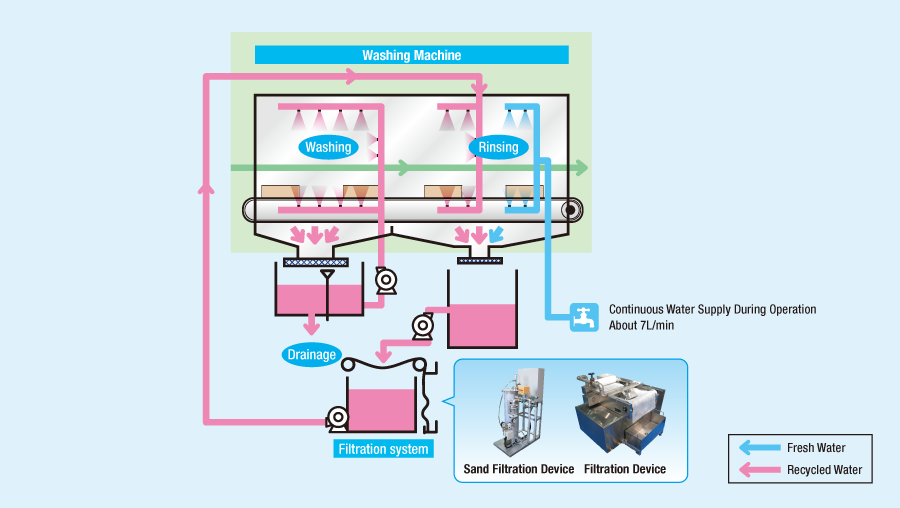

Filtration system (compatible with outer box washers only)

Water that would normally be discharged is filtered and recycled as reclaimed rinse water.

Filtering and reusing the water can reduce the amount of water used in a normal washing machine, about 25 liters each wash, by about a third.

Not only does this machine reduce water and sewage costs, but also reduces the amount of fuel needed for heating.

Filtration Device

After rinsing, water is filtered, and when the filter gets clogged with impurities, a new filter is sent automatically.

30 Mesh Strainer

A simple filtration device.

Filtration is made possible through the fine mesh of the strainer.

Sand Filtration Device

Fine sand is used to filter water used for rinsing, saving water and reducing steam usage.

- When you want to reduce time and effort required for cleaning inside the washing machine…

-

Automatic Self Cleaning Device

Capable of cleaning chamber inside easily by pushing a button.