Parts Box Washing Machine will support each customer’s wash-dry process with its wide array of functions prepared by us in consideration of customers’ environments.

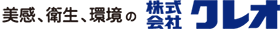

Adoption of complete-circulation method

Polluted water remained from washing will be filtered by the primary filtering device (separator) and swarf and iron powder etc. would be eliminated. Then oil water separation would be performed. Filtered water will be used as rinsing water. Then the water used for the rinsing would be returned to a washing tank and will be used as washing water again.

This method extends washing water replacement cycle dramatically. So it is especially recommended for customers who don’t have sewage facilities.

It filters fine sand, mud, swarf of the likes washed away from the parts boxes.

Strong centrifugal force due to high-speed rotation separates even dirty liquids into three phases: oil, water, and solids. Only clean water is returned to the tank.

For Customers With Boilers

Water is heated by indirect steam.

| Injecting steam directly into the tank, which is the method generally used for heating, is problematic due to steam liquification, which turns into wastewater. Using indirect steam heating and having a steam drain recovery system on the boiler makes it possible to simultaneously prevent liquefication of steam and improve boiler efficiency. |  |

|

For Customers Without Boilers

Water is heated by an electrical heater.

| Having a complete circulation system reduces the amount of heat required, meaning an electric heater can be used instead of a boiler. Customers without boilers can also use this system with peace of mind. |  |

|