Leave Your Container Washing Machines to CREO!

|

Daily Wash Loads

|

|||

|

Batch Type

|

Conveyor Type

|

||

|

Washing

Only |

Washing and Drying

|

Washing and Dehydrating

|

|

-

Space-SavingBatch Type Washer

-

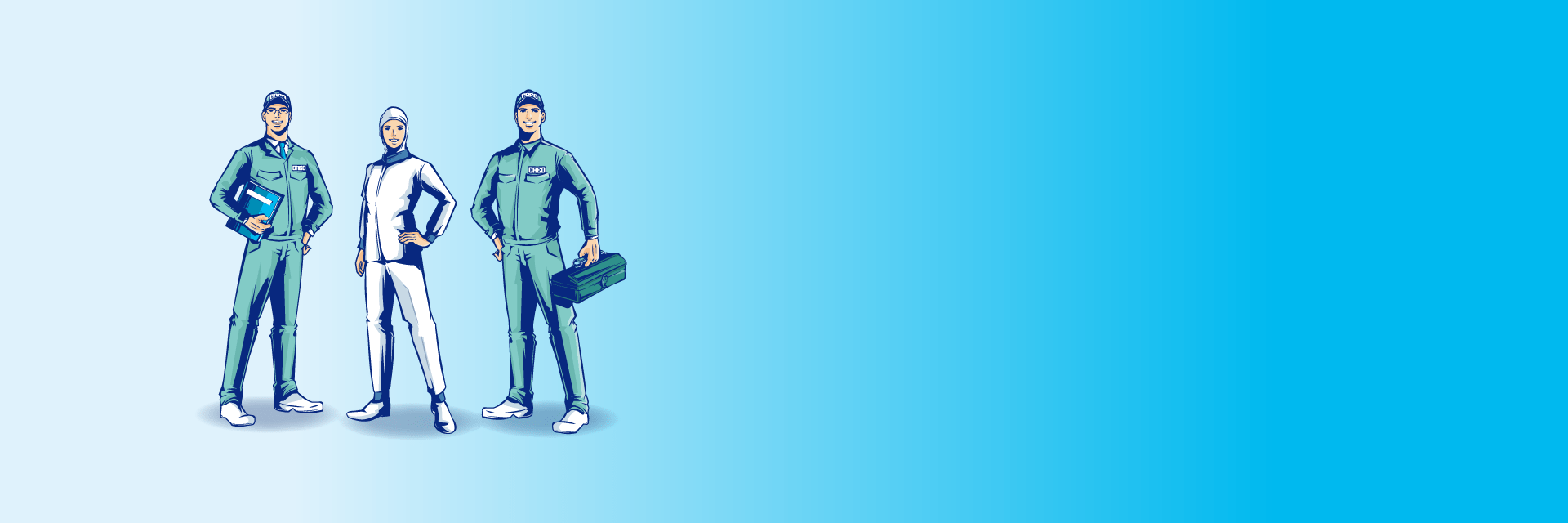

Mass ProcessingConveyor Type Washer

-

Powerful Drying

Utilizing Heated AirWasher and

Dryer

-

High Rotation Speeds for Energy-Saving DryingWasher and Dehydrator

-

Batch Type Washer

- Processing Capacity: 100 pcs/hour

- This type saves space, making it ideal for customers working in small spaces.

-

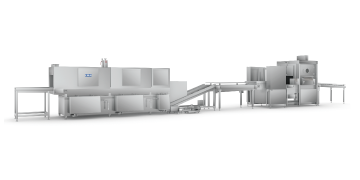

Conveyor Type Washer

- Processing Capacity: 300 to 2000 pcs/hour

- Containers are carried on a conveyor belt for high-volume processing!

* Material handling equipment is required to process more than 1,000 pcs. -

Washer and Dryer

- Processing Capacity: 500 to 2000 pcs/hour

- After washing, containers are dried all at once using hot air blowing at a speed similar to that of a jet plane!

* Material handling equipment is required to process more than 1,000 pcs. -

Washer and Dehydrator

- Processing Capacity: 500 to 2000 pcs/hour

- No hot air is used in the drying process, helping to reduce running costs!

* Material handling equipment is required to process more than 1,000 pcs.

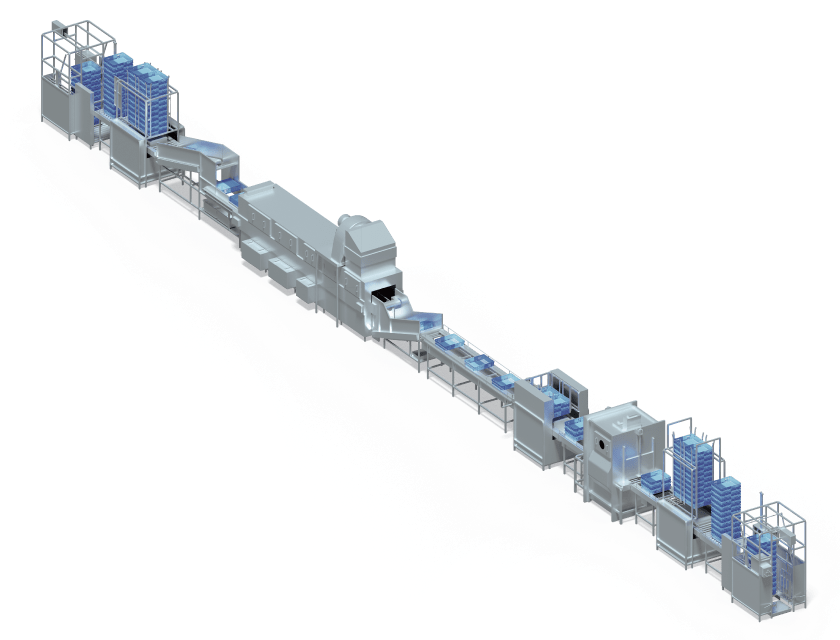

Large Lines Can Be Handled As Well!

-

Cart Transfer

❶ Cart Transfer

Containers stacked on a cart are taken from the cart and placed on a conveyor belt.

-

Lifter

❷ Lifter

Stacked containers are lifted to the height of the conveyor belt.

-

Unstacker

❸ Unstacker

Stacked containers are unstacked one by one.

-

Backward Entrance Conveyor

❹ Backward Entrance Conveyor

Containers that are face-up on the conveyor belt are flipped face-down.

-

Washing

❺ Washing

High volumes of low-pressure water remove grime.

-

Backward Exit Conveyor

❻ Backward Exit Conveyor

Containers that have been washed face-down are flipped face-up.

-

Pre-stacker

❼ Pre-stacker

Containers are stacked at a set height before they are fed into the spin-dryer.

-

Dehydration

❽ Dehydration

Centrifugal spin drying removes water droplets from inside and outside surfaces.

-

Stacker

❾ Stacker

Washed, centrifuged, and dried containers are stacked to a predetermined height.

-

Lifter

❿ Lifter

Containers are lowered from the height of the conveyor belt to the height of a cart.

-

Cart Transfer

⓫ Cart Transfer

Stacked containers are loaded onto the cart.

Benefits of Introducing A Washing Machine

Comparison in efficiency between hand washing and machine washing

In case of Hand Washing |

In case of Machine Washing |

||

|---|---|---|---|

Processing Capacity |

|

7.5 Shorten |

|

Quality |

|

High power |

|

Water Consumption Cost |

|

Cost reduction |

|

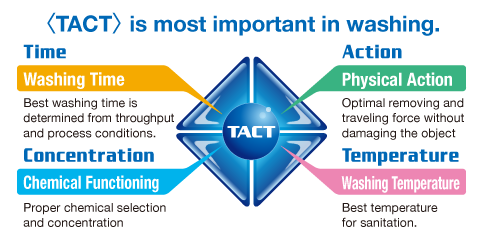

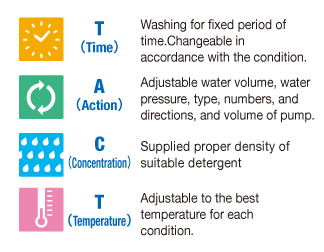

CREO’s Ideal Procedure for Washing

We propose the best washing for each condition.

Container Washing Methods

| Low-Pressure Washing | High-Pressure Washing | ||

|---|---|---|---|

| Advantages |

|

|

|

| Disadvantages |

|

|

|

Let CREO find you the ideal washing system

for your needs and the type of grime being washed!

Satisfactory choice with washing simulation before introduction Check with washing/drying experiment using real machine

You can directly check the effect of our machine with your own eyes

in washing/drying experiment at our experiment site using real machines at your attendance.

Following the result of washing test, we’d systematically guide you through from verification,

proposal to follow-up how you can introduce optimum machine.

CREO is the only machine you can check and choose!

Hanyu Plats

Washing/Drying test with real machine

ATP wipe-off test