Line Up

Movie

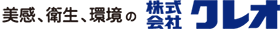

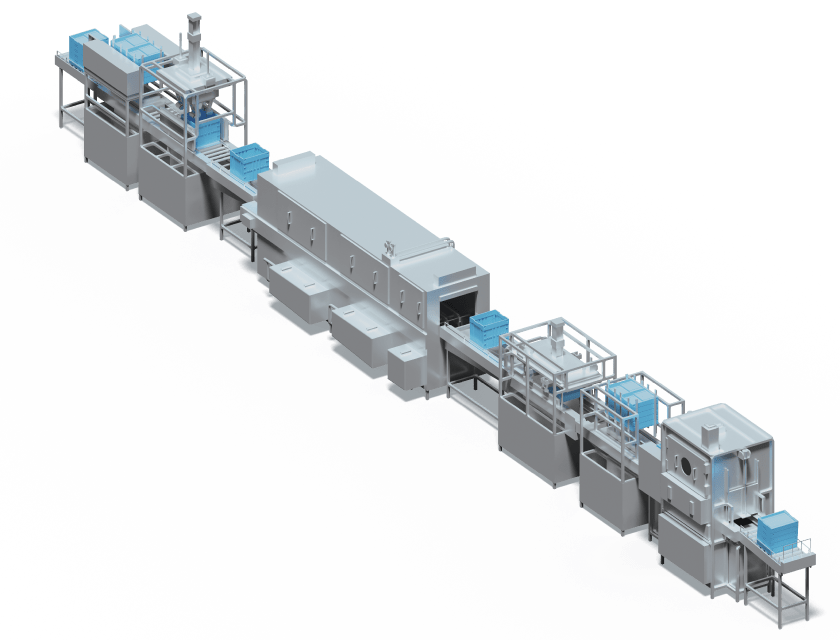

A Folding Container Washer and Dehydrator Equipped With an Opener and Closer

A wash and spin drying line that incorporates equipment (material handling) before and after the washer.

Saves labor and increases processing capacity at the same time!

Is This Possible?

Optional Products to Meet Needs

- When you want to reduce running costs… this reduces the amount of fuel used!

-

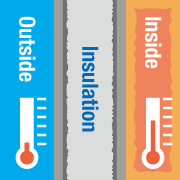

Isolation Chamber

Doubled metal sheet, and filled insulation material between them. Thermal efficiency is improved by reducing heat radiation from metal sheet.

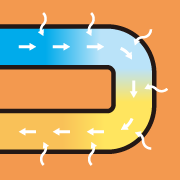

Wastewater and exhaust heat recovery device

Warming up using water by heat recovery from wastewater.

- When you want to reduce running costs… this reduces the amount of water used!

-

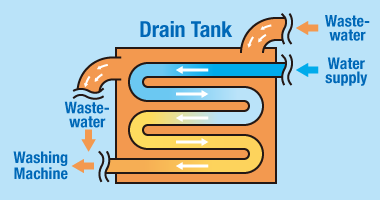

Filtration system (compatible with outer box washers only)

Water that would normally be discharged is filtered and recycled as reclaimed rinse water.

Filtering and reusing the water can reduce the amount of water used in a normal washing machine, about 25 liters each wash, by about a third.

Not only does this machine reduce water and sewage costs, but also reduces the amount of fuel needed for heating.

Filtration Device

After rinsing, water is filtered, and when the filter gets clogged with impurities, a new filter is sent automatically.

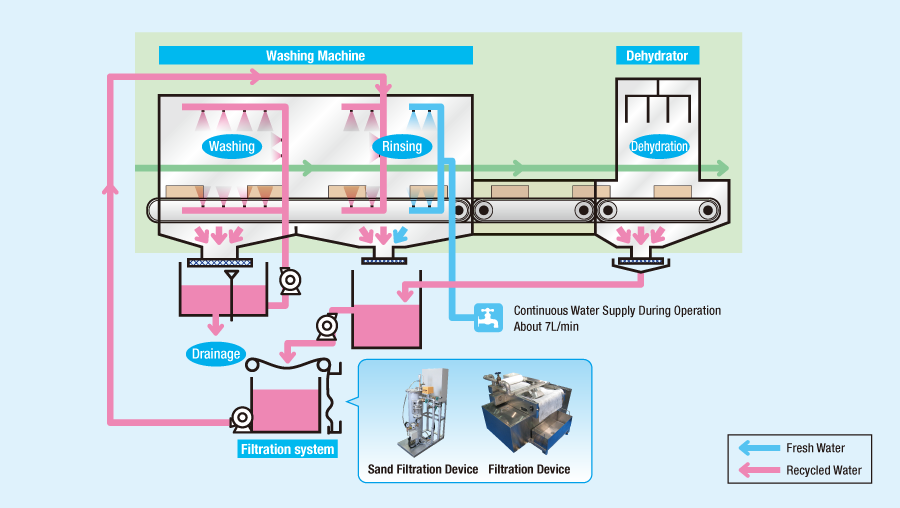

30 Mesh Strainer

A simple filtration device.

Filtration is made possible through the fine mesh of the strainer.

Sand Filtration Device

Fine sand is used to filter water used for rinsing, saving water and reducing steam usage.

- When you want to reduce time and effort required for cleaning inside the washing machine…

-

Automatic Self Cleaning Device

Capable of cleaning chamber inside easily by pushing a button.

- When removing shipping labels is hard work…

-

Label Peeler

Labels that are difficult to remove manually are thoroughly removed using high-pressure water.

Plunger Pump

A pump that discharges high-pressure water to remove labels.

Label Peeling Nozzle

High-pressure jets sprayed from the plunger pump thoroughly remove labels.

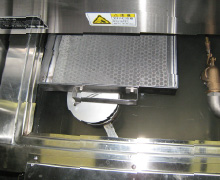

Label-Scraping Strainer

A strainer that ejects labels removed by the label remover from the machine.

[ Manual ]

[ Automatic ]

Automatic Net Filter

Small, pulverized label remnants that have passed through the strainer are further filtered through a net.

The filter comes with automatic reverse cleaning.

- An automated device for increased processing capacity

-

Material handling before and after washing

A conveyance system that achieves both high-volume processing and automation. Products are available based on your needs.

-

Unstacker

❶ Unstacker

Stacked and folded folding containers are unstacked one at a time.

-

Opener

❷ Opener

Folding containers are automatically assembled for washing.

This reduces man-hours on work that would previously have been done by hand. -

Washing Machine

❸ Washing Machine

High volume, low-pressure water remove grime.

-

Closer

❹ Closer

The folding container is automatically folded for spin drying . This reduces man-hours on work that would previously have been done by hand.

-

Pre-stacker

❺ Pre-stacker

The folding containers are stacked to a predetermined height before being fed into the spin dryer.

-

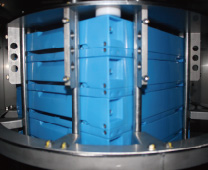

Dehydrator

❻ Dehydrator

Centrifugal spin drying removes water droplets from the folding containers.

-

Unstacker

- Ways to Use Openers!

-

Assembling large numbers of folding containers takes time and labor.

CREO not only helps with the washing process, but can also offer solutions for the picking process for loading products.