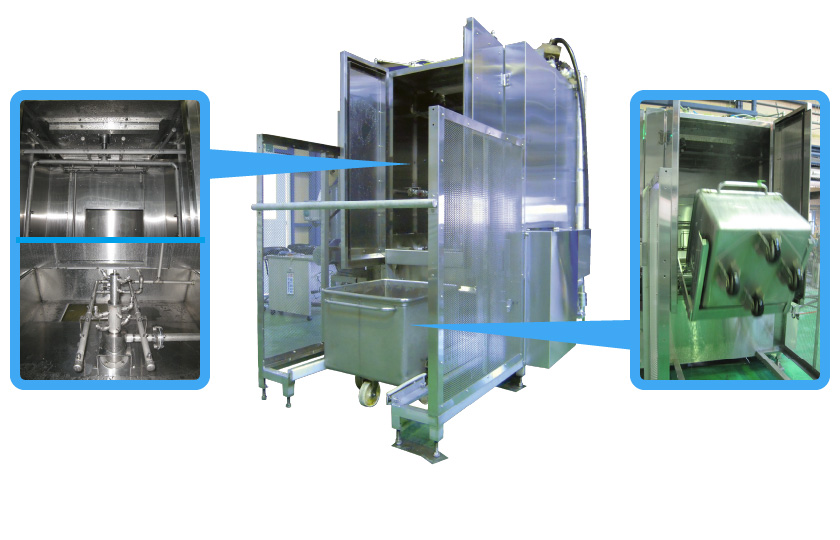

To reduce labor and increase efficiency when washing wagons

Reduces total wash time and

water consumption over hand washing!

water consumption over hand washing!

The wagons are rotated, then fed into the machine.

Once washing is finished, they are automatically inverted as they come out of the machine.

The top and bottom nozzles rotate as they wash, allowing for an even wash.

The wheels and backside, which are difficult to wash manually, can be cleaned easily.

Specifications

| Model Name | Meat Wagon Washer | |

|---|---|---|

| Processing Capacity | 17 items/hour | |

| Dimensions (main body) | Width (mm) | 1,750 |

| Depth (mm) | 2,950 | |

| Height (mm) | 2,450 | |

| Total Electrical Capacity 3P200V (kW) | 11.85 | |

| Equipment Power Supply | Wash Pump (kW) | 5.5 |

| Pre-Wash Pump (kW) | 5.5 | |

| Rinse Pump (kW) | 0.25 | |

| Reverse Drive Motor (kW) | 0.4 | |

| Nozzle Drive Motor (kW) | 0.1 | |

| Water Usage Volume (L) | Initial 400L, During Operation 32L/time | |

| Steam Usage Volume (kg/h: 0.3MPa) | 200 | |

| Compressed Air Volume (NL/min: 0.6MP) | 10 | |

| Exhaust Volume (m3/min) | 30 | |

| External Connection | Water Supply Union Stopper | 25A |

| Drain T-pipes joint stopper | 50A | |

| Steam Flange Stopper | 25A | |

| Compressed Air Flange Stopper | 10A | |

| Exhaust Phase Flange Stopper | 120×750 | |

| Electrical Terminal Block Stopper | ||

Please contact us for shapes and sizes of wagons that can be washed.

Dimensions and specifications may be changed during design.